rapidea ® smart plant engineering

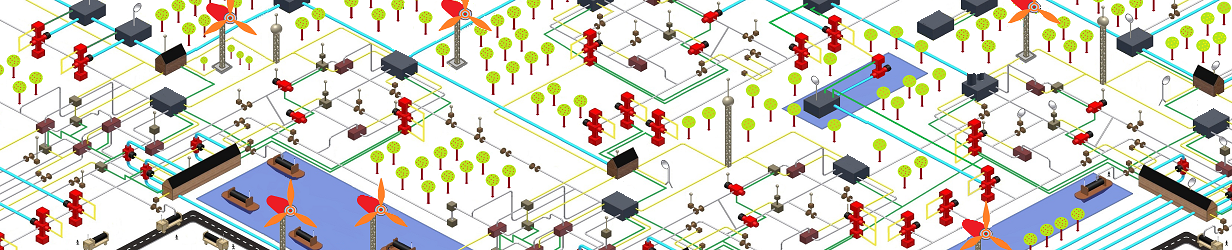

- Plant Engineering

- Multi Ring-Areas Oases

- Piping System

- Module Change System

- High Pressure Coupling

- Control Ball Valve

- Turn Actuator

rapidea ® Strategy Smart Plant Engineering

Systems in which data, information, control commands and software packets are exchanged over networks between ED storing and processing units as well as the various units that meet the requirements of the "strategy Intelligent systems".

Smart Products Strategy [Development Phase II]

The Smart Products Strategy in connection with supply and production plants includes intelligent, self-monitoring, self-adjusting, user-friendly, resource-saving, energy-saving and communications-capable products. For example of smart products in supply or production plants (Examples: see below).

Industry 4.0 Strategy [Development Phase III]

The Industry 4.0 Strategy in connection with supply and production plants includes digitalisation and networking along the entire added value chains: In this supply and production plants the networks are a) intelligent Production Systems, such as factories and products as well as services, can be permanently interlinked via an IT network and data, information, control commands and software can be exchanged over this network (vertical networking) and b) business partners and customers, who are active in the IT network can also be linked together (horizontal integration).

Smart Products Plant Engineering Strategy [Development Phase IV]

The Smart Products Plant Engineering Strategy covers technologies that are in the position to change the components, modules and aggregates integrated in the plants during on-going production as necessary due to pending operating pressures and these components, modules and aggregates as well as the materials can be transported over long distances to different stations in the plants and systems that are networked together. Such technologies are: a) Smart Module Change Systems for changing function modules as well as b) Smart Piping System, consisting of primary, secondary and tertiary pipeline systems for transporting media and function modules.

Smart Plant Engineering Strategy [Development Phase V]

In order to optimally exhaust all mentioned above possibilities with regard to the development of future supply and production plants, it is sensible to ensure that the smart products, Industry 4.0 and the smart products plant engineering strategies are well-balanced with regard to promoting future-oriented smart plant engineering.

Smart Multi Ring-Areas Oases Strategy [Development Phase VI]

When developing and implementing environmentally friendly and future-oriented solutions for protecting the ecological system and climate protection, the requirements of a balanced ecological system must always be given significantly greater weight than other requirements, as was the case with the development of the innovative Smart Multi Ring-Areas Oases.

rapidea ® Strategy Smart Plant Engineering

Multi Ring-Areas Oases

Smart Piping System

Smart Module Change System

Smart High-Pressure Coupling

Smart Control Ball Valve